C10 Configurable Counting Scale

Detail

Click to download Product Catalogue

C10 is a configurable counting scale designed for highly demanding industrial counting and weighing applications.

What's Inside

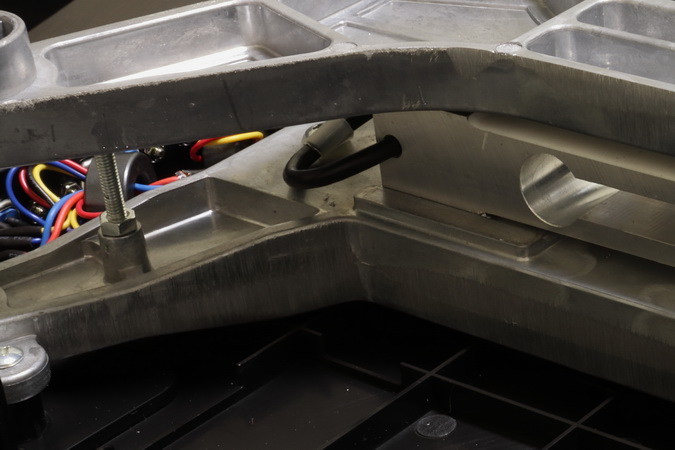

Super strong load receiving structure is the back born of fast and stable results. While the 32-bit micro-processor, 24-bit A/D converter, superior electronics, Alibi memory which stores more than 130,000 transactions, unsurpassed innovative program, new linearity compensation method, comprehensive range of flexible & selectable operation parameters, user selectable AD conversion speed, 1.2 million counting resolution… etc. together make C10 an extraordinary piece count and weighing scale.

Expandability & Flexibility… 1 + 1 = 3

When equipped with an optional external platform, C10 turns 2 platforms into 3 scales. Switching among the built-in platform, external platform and 2 platforms together is just a matter of fingertips.

Speeds Up Production & Less Human Error

C10 memorizes your operation settings and entries for hundreds of different application.

By just 4 key pressings, all detailed operation settings and entries, from platform to use, customer, product code & description, unit weight, check limits, tare behavior or pre-tare value to expiry date of an application are recalled and employed immediately.

Barcode scanner provides even faster, easier and error free operator number, product and customer code entry and some commonly used operation key input.

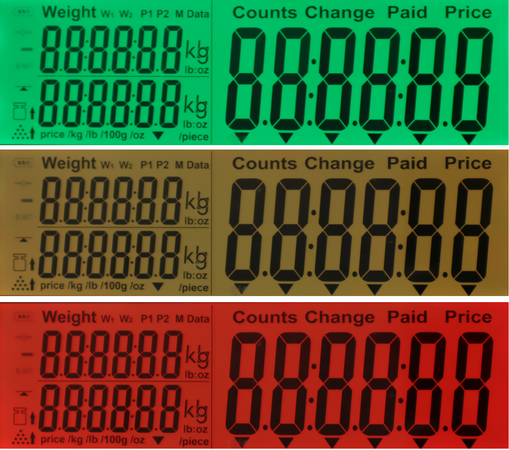

The wide-angle LCD plus the Tri-Color backlight display weight, unit weight, number of pieces and other operation status / information and check results crystal clear even in dim and dark environment.

Transaction Data is always Secured & Ready

Transaction date is collected in real time, centrally stored and is ready for retrieval from locally or remotely.

Productivity & production volume analysis per each employee, production line, plant, customer and product with yield rate data is made possible just by several clicks on PC keyboard.

Connectivity

- Standard 2 x Independent Configurable RS232 Comports.

- Baud Rate = 1200 ~ 921600

- 10 x predefined and 1 x custom output protocol.

- Optional Independent Configurable RS485

- Optional WIFI and Bluetooth Module

- Optional 3 x Configurable External Inputs

- Optional External Platform Input

All these together guarantee the flawless connection with all kinds of peripherals like remote display, ticket and label printers, computer database, foot pedals, ERP system etc.

Android and iOS APPs

Powerful Android and iOS Apps are built to turn your smart devices into a handheld terminal, remote display, remote data input center and controller of your C-10 connected.

These Apps support connection via Bluetooth and WIFI. To download, just search for: -

- aConnect at Google Play

- FMDirect at App Store

Operation Features

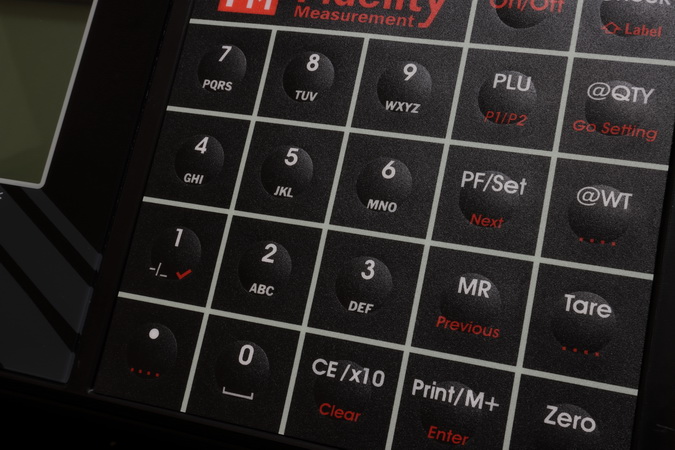

- Full Numeric and Functions keyboard

- Tri-Color Backlight

- Support Single Range, Dual Range and Dual Interval Operation

- External Platform Supports Free Capacity and Division Setting

- Near Zero Weight Value for Dynamic Weighing to avoid False Signal Output

- Manual, Preset, Repetitive and Continuous Tare Operation

- Continuous Tare with Configurable Delay Time before Tare Action

- Fast Manual Tare, Zero and Print/M+ Key, Operator Number, Customer and Product Code Entry via Barcode Scanner

- Real Time Clock with Backup Battery

- Configurable Keypad, Check & System Buzzer

- 9 x Selectable Filter Strength Levels plus 4 x AD Conversion Speed

Management Features

- Configurable Machine ID, Machine Group and Operator Number to Enhance Ease of Multi-Scales Applications and Management Records

- Daily, Monthly, Specific Period Report Output

- Multi Search Criteria for Report Generation

- Support Inquiry, Setting and Execution Commands from PC

- Check Result Control for Accumulation, Data Printout & Data Output

- Keypad Lock Function

- All Current Operation Results Output in Database Format for Data Management, Processing & Analysis

- 10 x Quick Access PLU (for each weight unit) for Unit Weight, Quantity Check Limits, Weight Check Limits, Pre-Set Tare

- 100 x Quick Access PLUs for each of Customer Code & Description and Product Code & Description.

- 99 x Customized Operation Settings and Entries PLUs per each Platform (P1, P2 and P1+2 together)

- All Current Operation Results Output in Data Base Format Increases Ease & Efficiency of Data Management, Processing & Analysis

- Label Printers Supported: -

- Datecs = LP-50

- TSC = TDP-225, TDP-247, TDP-345, TTP-225, TTP-247, TTP-345

- Sbarco = all Models with Serial Port

- Selectable Portrait / Landscape Ticket Printout Format

- User Programmable and 10 x built-in Predefined Continuous / Interval Output Protocol

- Support Product Expiry Duration Input and Output

Specifications

|

Model |

Capacity (Max) |

Readability (d) |

nmax |

|

C10-3000L |

3000g |

0.1g |

30,000 |

|

C10-6000L |

6000g |

0.2g |

30,000 |

|

C10-15KL |

15kg |

0.5g |

30,000 |

|

C10-30KL |

30kg |

1g |

30,000 |

|

C10-6000M |

6000g |

0.1g |

60,000 |

|

C10-15KM |

15kg |

0.2g |

75,000 |

|

C10-30KM |

30kg |

0.5g |

60,000 |

|

C10-10KH |

10kg |

0.1g |

100,000 |

|

C10-20KH |

20kg |

0.2g |

100,000 |

|

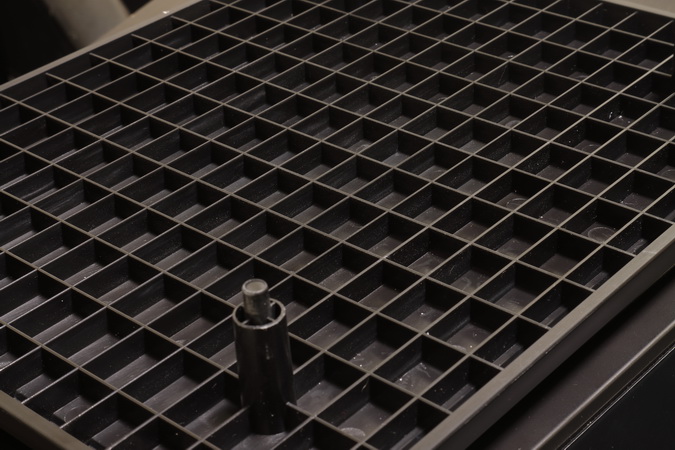

Platter |

240 x 295mm ABS Platter with SUS304 Stainless Steel Insert |

||

|

Displays |

Bold Type Wide Angle LCD

|

||

|

Weight Units |

|

||

|

Max. Tare Range |

-Max or -Max1 (Subtractive Tare) |

||

|

AD Conversion Speed |

15, 30, 60, 120 times/second |

||

|

Counting Resolution |

1.2 million |

||

|

Repeatability (Typical) |

1.5d |

||

|

Power Source |

|

||

|

Operation Environment |

|

||

|

Accessories |

|

||

|

Packing |

Individually Packed: -

4 Units in Shipping Carton: -

|

||

|

Optional External Platform Input |

|||

|

Capacity and Readability |

Free Setting |

||

|

Load Cell Connection |

|

||

|

A/D Converter & Internal Resolution |

|

||

|

In the interest of improvement, specifications may change prior to notice |

|||

Options

- SP-POS58IV & SP-POS88IV Thermal Ticket Printer

- RD-DOT Dot Matrix Remote Display

- Built-in RS485 Communication Module

- Built-in Bluetooth 2.0 or 4.0BLE Module

- Built-in WIFI Communication Module

- External WM Wireless Communication Module

- Secondary Weighing Platform Input

- Bluetooth 2.0 Wireless Barcode Scanner

- Serial Cable Barcode Scanner